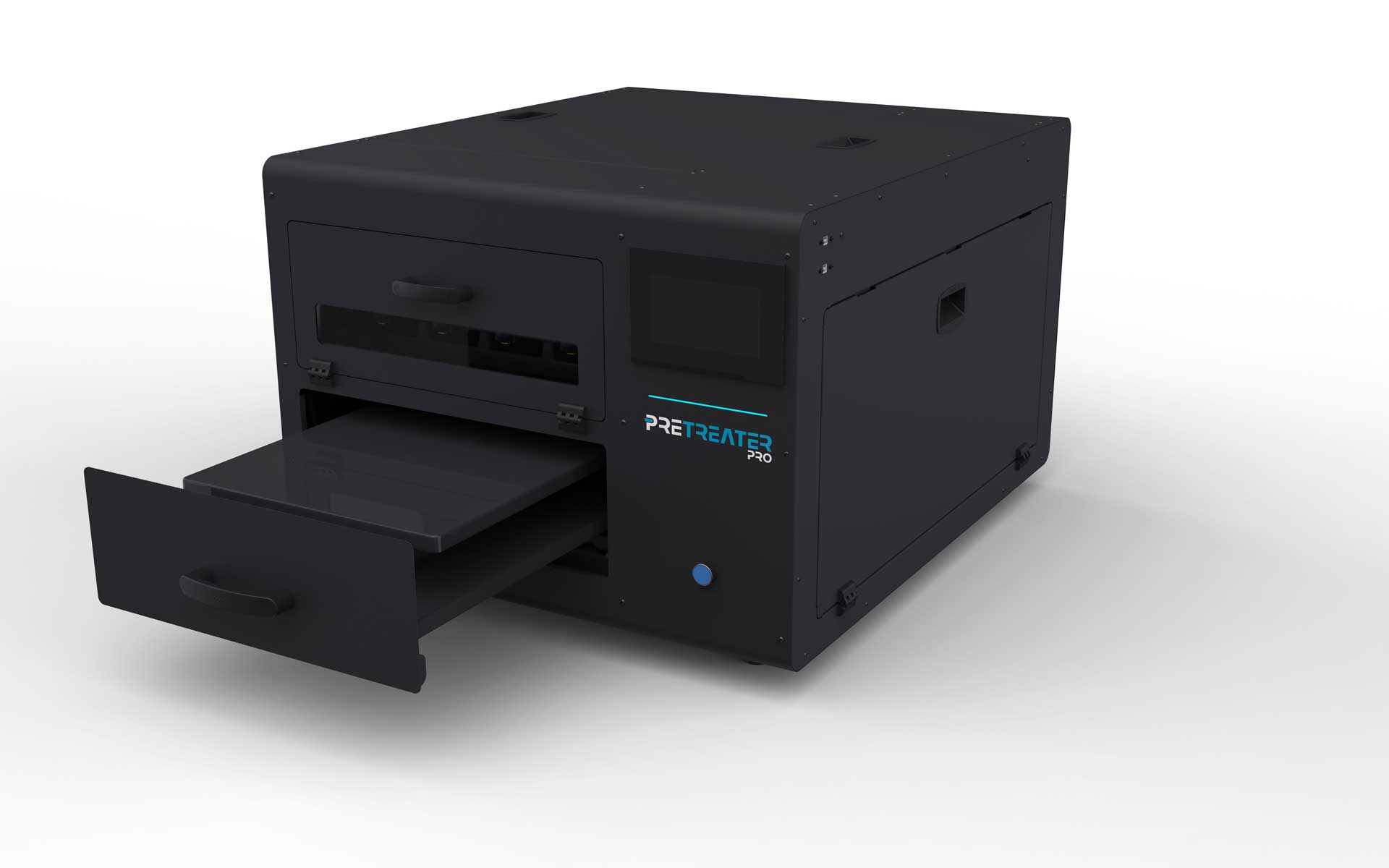

Pretreater Pro

A fully automated pre-treat machine from an expert DTG printer manufacturer!

Pretreating is the foundation to achieve vibrant colors, sharp details and washability for your prints.

Say goodbye to messy spray guns, inconsistent prints and dull colors!

Achieve optimum printing results and wash fastness while saving liquids and avoiding user errors!

Invest in your DTG business success with the right pre-treatment machine!

Take advantage of our cutting-edge technology and Polyprint’s expertise in the DTG printer manufacturing industry. Pretreater Pro takes the stress out of the pretreating process. Enjoy precision spraying capabilities that will seamlessly prepare your garments for amazing prints. Its fully automated production process will allow smooth production runs and enjoy less down time with the simplest maintenance system. Easily pretreat your t-shirts and exceed your customer expectations. Create loyal customers with consistent, high-end printing results!

The Pretreater Pro will help you increase efficiency and quality control!

ENJOY

A fully automated pretreating procedure!

The Pretreater Pro has an innovative system that:

- Allows you to easily switch between 2 liquids with a touch of a button. No more spending your time looking for the right liquid.

- Accurately select your preferred spraying area within 1cm step vertically and 10cm step horizontally for easy pattern selection.

- Enjoy multiple Custom Presets to automate your workflow.

- Job and Liquid consumption Counters will ease your mind by keeping track of your production.

- The Barcode ready feature will enable you to fully automate your workflow for seamless production runs.

TAKE ADVANTAGE OF

High-quality pre-treatment!

Uniform spraying and repeatability are a must for one-offs or large batches of textile. Achieve:

-

- Uniform spraying with large diameter nozzles and precise movement due to a stepper motor.

- A Liquid pressure regulator that guarantees constant spraying pressure during the pretreating process.

- A Re-circulation system that achieves liquid homogeneity and prevents sedimentation due to the constant re-circulation of the fluid, prolonging the liquid lifespan and ensuring that every batch is coated exactly the same, producing consistent results every time and high-quality prints.

BENEFIT FROM

Economy in precoating liquids!

Precoating liquids are wasted during the pretreating process, due to the inability of selecting the exact area you need. Gain:

- An Accurate selection spraying area that gives the user the choice to select nonconsecutive areas and spray exactly the amount needed.

- A selection criterion using ml that helps the user precisely define the amount of liquid sprayed on a specific area.

- The ability to switch between 2 liquids with a touch of a button. An auto-function flushes the tubes with the right amount of liquid, minimizing liquid waste.

- A Re-circulation system installed in both tanks that circulates the liquid, ensuring liquid homogeneity, avoiding sedimentation and consequently nozzle clogging, thus prolonging liquid lifespan.

- Replaceable 5L commercial tanks help you easily replace liquids, when low, reducing liquid loss.

- An Isolated spraying chamber that protects the electrical and moving parts from mist, reducing maintenance issues, prolonging the endurance of mechanical parts and maximizing their up time.

APPRECIATE

User-friendly pretreating process!

A small learning curve and multiple user-friendly features make your garment pretreating an easy process.

- Uniquely enclosed spraying chamber (Box in a Box system) for a clean and healthy workspace.

- “Nearly Full” liquid indicator for the waste tank to avoid messy waste spills.

- “Nearly Empty” liquid indicator for both tanks to prevent miss-sprayed garments.

- Αccess cover sensors are here to ensure that spraying is ceased once you have opened a cover. No more inhaling mist and putting your health at risk.

PREVENT

User Mistakes

The most common problems are created by user mistakes. Garments are often destroyed, and money lost in the process. Now:

- You can’t make a mistake. Always know which precoating liquid is selected and be notified when switching liquids.

- Easily switch between 2 liquids with a touch of a button and let the automated process save you time.

- Follow Intuitive Messages when switching ON or OFF the machine to keep it in perfect condition. Guided messages will walk you through the process.